"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

03/16/2016 at 11:26 • Filed to: None

1

1

29

29

"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

03/16/2016 at 11:26 • Filed to: None |  1 1

|  29 29 |

I know I know, why CVT or AT when you can MT, but there are some people who want to have thier car shift for them. I’ve been driving around my wife’s CVT and like it more than a regular AT. Now I dont know a whole lot about these but to me, it seems as if having infinite gear ratios would be much better than an 8 or 10 speed. The transmissions look to be smaller, which I would think would make them lighter, giving more to the all holy MPG. They also look to have fewer parts. This all feeds into simplify and add lightness method of thinking? So if what I’ve said is all true, why invest into these crazy 8 and 10 speeds?

also introducing shift points in a CTV boggles my mind.

Ash78, voting early and often

> OPPOsaurus WRX

Ash78, voting early and often

> OPPOsaurus WRX

03/16/2016 at 11:29 |

|

I've wondered that myself, and have been told that long-term durability and ability to handle high torque still favor traditional planetary autoboxes. I've still never driven a CVT, but on paper they still sound like the best possible way to get everything you need from a non-electric engine.

OPPOsaurus WRX

> Ash78, voting early and often

OPPOsaurus WRX

> Ash78, voting early and often

03/16/2016 at 11:32 |

|

if thats true about torque, I’d guess that could be solved by just beefing the whole thing up. They still look so small that even a 25% increase in size would still make them smaller and lighter than geared AT’s.

Bluecold

> OPPOsaurus WRX

Bluecold

> OPPOsaurus WRX

03/16/2016 at 11:34 |

|

“simplify and add friction losses”.

Cé hé sin

> OPPOsaurus WRX

Cé hé sin

> OPPOsaurus WRX

03/16/2016 at 11:39 |

|

CVTs have traditionally been less efficient, plus there’s the rubber band effect with the engine keeping a steady note while speed changes.

BigBlock440

> OPPOsaurus WRX

BigBlock440

> OPPOsaurus WRX

03/16/2016 at 11:50 |

|

CVTs only have a limited range of ratios available. With an auto, you could use a much lower 1st gear, a much higher 10th, and a few additional gears in between. The CVT would move between, say 3rd to 7th equivalent, while the auto would still have 1st and 2nd ratios for acceleration and 8th (and 9th/10th) ratios for economy.

tromoly

> OPPOsaurus WRX

tromoly

> OPPOsaurus WRX

03/16/2016 at 11:52 |

|

It’s not quite that easy, as the torque is transferred through a smooth pulley surface and a belt edge, it’s quite literally friction that makes a CVT work. Basically for that reason gears will always be able to transfer torque better than a CVT belt.

Master Cylinder

> Bluecold

Master Cylinder

> Bluecold

03/16/2016 at 11:55 |

|

And: “simplify and add why is my engine always at redline even when I’m only going 5mph?”

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> OPPOsaurus WRX

BmanUltima's car still hasn't been fixed yet, he'll get on it tomorrow, honest.

> OPPOsaurus WRX

03/16/2016 at 11:57 |

|

They tend to slip with higher torque input. So good for economy cars, not for anything larger.

OPPOsaurus WRX

> BigBlock440

OPPOsaurus WRX

> BigBlock440

03/16/2016 at 12:03 |

|

i’m not sure how long CVTs have been around, not as long as AT’s i’m guessing. Is this something that could be resolved as they are developed more along with the band slipping with higher torque?

Snuze: Needs another Swede

> OPPOsaurus WRX

Snuze: Needs another Swede

> OPPOsaurus WRX

03/16/2016 at 12:04 |

|

I think this has more or less been covered but the three main factors are durability, efficiency, and ratio spread.

Traditional automatics are significantly stronger than CVTs, which is why you find regular ATs in almost everything but CVTs typically only behind 4 cylinders.

In terms of effiency, there is a lot of drag on the belts in a CVT. Modern ATs with lockup torque converters are almost on par with a plain only MT in terms of effiency (talking about losses within the trans, not fuel economy) but that does translate into better fuel economy.

Lastly, ratio spread means you can have a lower first gear and higher overdrive. GM’s 8L90 has a 4.56 1st gear and 0.65 8th gear. Dividing 1st by 8th gives a ratio spread of 7.02. ZF’s 9 speed has a spread of over 9.0. CVTs are usually lower, more like 5.0 to 6.0, though some of the newer ones are approaching 7.0.

Mattbob

> BigBlock440

Mattbob

> BigBlock440

03/16/2016 at 12:11 |

|

which begs the question, when will they try a compound CVT (one CVT behind another), and get a huuguue amount of ratio change and still probably be smaller than a big auto.

TFSIVTEC drivesavolvo

> Ash78, voting early and often

TFSIVTEC drivesavolvo

> Ash78, voting early and often

03/16/2016 at 12:17 |

|

They are really weird the first time, you peg the throttle, the revs go up and hold about 1000 rpm before the redline and then you expect a shift but it just keeps accelerating until you decide to let off

BigBlock440

> OPPOsaurus WRX

BigBlock440

> OPPOsaurus WRX

03/16/2016 at 12:17 |

|

The problem is that you’d need to make the pulleys bigger, and making them much bigger won’t physically fit. Or you’d need to add additional pulleys, making it bigger and more complex. Do-able, but nobody’s thought it was worth it yet. Also, the pictures you’re using for size comparison is a FWD transmission vs RWD transmission. A FWD autobox is comparable in size to a CVT, it needs to be to fit.

TheHondaBro

> OPPOsaurus WRX

TheHondaBro

> OPPOsaurus WRX

03/16/2016 at 12:18 |

|

God. Damnit.

Autofixation

> BigBlock440

Autofixation

> BigBlock440

03/16/2016 at 12:27 |

|

No, the CVT could cover a wider ratio of gear ratios than a four speed or a 23 speed. And it doesn’t have a set number of ratios. The only way it could have a set number is if it only “locks” to the simulated shift gears.

RamblinRover Luxury-Yacht

> OPPOsaurus WRX

RamblinRover Luxury-Yacht

> OPPOsaurus WRX

03/16/2016 at 12:43 |

|

CVTs have been around for a very, very long time. The modern style largely grows out of a similar setup to the DAF Variomatic, which dates from ‘59.

https://en.wikipedia.org/wiki/DAF_600

The GWK was running a CVT similar to that found in a Snapper riding lawn mower as early as 1911:

https://en.wikipedia.org/wiki/GWK_%28ca…

The trouble is and always shall be friction losses - anything, and I do mean anything that is capable of sliding ratios must involve some level of kinetic friction power transfer instead of static friction or pressure under constant drive, and that makes for heat, reduced strength under torque for a comparable component size, and wear. ALWAYS. The holy grail is a CVT that reduces these losses acceptably close to gear train losses (power burned making gears slip - yes slip - their faces together) and wears slowly enough that engagement wear on other systems is on par.

Beefing up is only a partial solution because then you have inertial losses and greater friction losses elsewhere.

just-a-scratch

> BigBlock440

just-a-scratch

> BigBlock440

03/16/2016 at 12:47 |

|

If you divide the highest and lowest gear ratios, you get an idea of the ratio of possible gear reduction. It turns out that ratios in the area of 4 or 5 in this context are quite adequate for cars using piston engines.

CVTs seem to cover that range pretty well.

Still, you're correct that the gear ratios that can be chosen are much greater than what can be done for pulley ratios in a CVT.

BigBlock440

> Autofixation

BigBlock440

> Autofixation

03/16/2016 at 12:47 |

|

You realize that CVTs have a maximum an minimum ratio, right? It doesn’t matter how many different ratios you could come up with in between that maximum and minimum, it’ll still be between those. The autos can have a higher maximum and lower minimum than a CVT that will realistically fit in a car can.

just-a-scratch

> OPPOsaurus WRX

just-a-scratch

> OPPOsaurus WRX

03/16/2016 at 12:51 |

|

My experience with a CVT (2013 Impreza) are very much like your description. It has turned out to be very easy to drive, comfortable, and pretty efficient.

The only area I think it’s lagging behind the traditional autobox is when moving from a stop. It takes a bit longer to get ‘in gear’ and tends to surge slightly when you start moving if you don’t let it finish its ‘engagement’ or whatever. This really only seems to happen after changing gear, (e.g. reverse to drive).

RamblinRover Luxury-Yacht

> Mattbob

RamblinRover Luxury-Yacht

> Mattbob

03/16/2016 at 13:02 |

|

This is an idea that has some merit, because while you’d be doubling up on some of the friction losses, the torque “jump” doesn’t happen all at once. Several flaws, though. Putting several in series doesn’t cut down on the max torque that a given belt/pulley interface would be asked to handle, so you’d have to have a small CVT feeding into a big one. Which, while that big one wouldn’t have to operate over as large a range as if it were *just* the big one in the system for all ratios, still shoots space and weight savings in the face. Further, crazy multi-speed autos are no longer adding extra planetaries, they’re linking and relinking subsets of the planetaries they have, so you can get crazy numbers of ratios out of a small number.

In short, it would work, but not well enough comparatively to demand it be done.

RamblinRover Luxury-Yacht

> tromoly

RamblinRover Luxury-Yacht

> tromoly

03/16/2016 at 13:05 |

|

Yep. Also, friction losses in a traditional manual or auto set of gears are secondary to face to face pressure transfer and if you could eliminate the friction you’d be a happy camper. CVT friction, not so much.

OPPOsaurus WRX

> just-a-scratch

OPPOsaurus WRX

> just-a-scratch

03/16/2016 at 13:05 |

|

yea I get some of the same thing with the shifting which is pretty annoying because I life on a street with a 45mph and i dont always have the time to sit and wait for it to shift

OPPOsaurus WRX

> BigBlock440

OPPOsaurus WRX

> BigBlock440

03/16/2016 at 13:07 |

|

yea, I thought they might be int he same area as an autos, but with an infinite amount of ratios between those limits while an auto only has a specific amount

OPPOsaurus WRX

> TheHondaBro

OPPOsaurus WRX

> TheHondaBro

03/16/2016 at 13:08 |

|

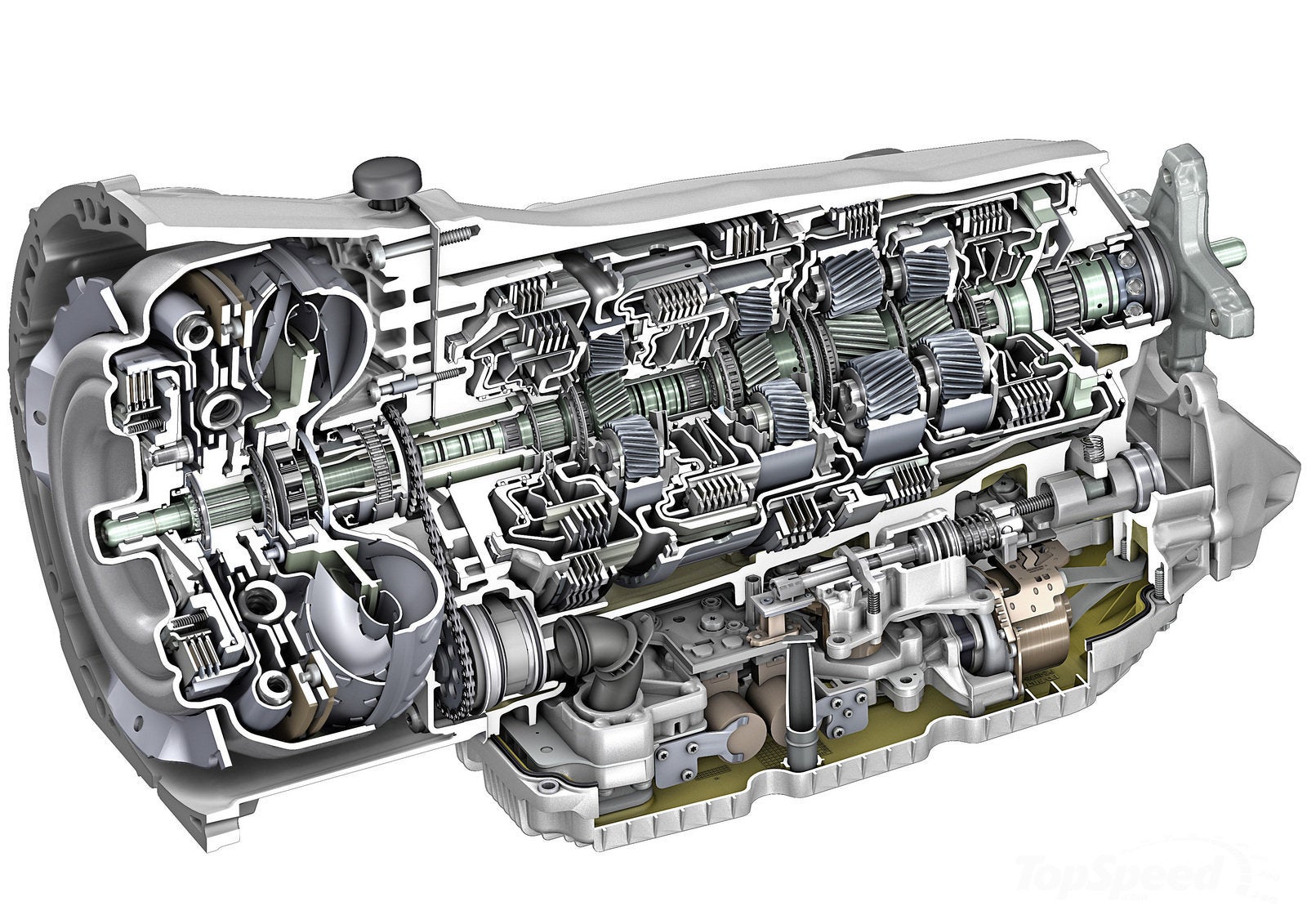

so many little parts everywhere

BigBlock440

> OPPOsaurus WRX

BigBlock440

> OPPOsaurus WRX

03/16/2016 at 13:11 |

|

I think I just thought of a better way to represent it.

CVT:

. . . 111111111111111

10-Speed:

1...2.3..4..5.6.7....8...9...10

wafflesnfalafel

> BigBlock440

wafflesnfalafel

> BigBlock440

03/16/2016 at 15:06 |

|

technically correct - but with a CVT you can get the broader range of ratios in a smaller, lighter package than a 10spd traditional auto box. For example Subaru generally has lower power engines, sells smaller vehicles and had been stuck with their old 4spd auto box forever so they were a perfect candidate to switch to CVTs. But in a luxury vehicle or larger truck where cost/weight/complexity are less of a burden and you need to be able to handle higher power loads the traditional automatic with additional gears can be a better choice.

Mattbob

> RamblinRover Luxury-Yacht

Mattbob

> RamblinRover Luxury-Yacht

03/16/2016 at 15:24 |

|

yeah, it wouldn’t really make sense for high torque applications. I hadn’t really thought about how you aren’t adding so much extra for the extra ratios in traditional autos. Thinking of an application where a compound CVT miiight be a good idea.... maybe small diesels if you could keep it small enough. You sure it wouldn’t cut down on the torque seen by a single pulley? Or rather, the output torque would be the same, but the necessary friction between belt and pulley would be reduced because you could have two smaller ratios in between.

RamblinRover Luxury-Yacht

> Mattbob

RamblinRover Luxury-Yacht

> Mattbob

03/16/2016 at 16:14 |

|

It’s not a question of torque seen by a single pulley, funny enough. As such. The highest torque for a shaft is at the larger pulley of a pair, but the highest slip is at the small pulley, because you need to have enough surface area to transmit a given force along the belt, and the surface area on the small pulley is, well, smaller. There are also issues having to do with how the belt bends (sort of, and centripetal force. It’s a mess). On that basis, having an intermediate size would be nice... if these were fixed size pulleys.

Since we’re CVT-ing, we look at minimum in vs. maximum out for you to be transmitting your desired power when you want it. Your controlling factors on allowable torque, then, are a big enough minimum size on the input pulley coinciding with when you have power, and a big enough output pulley so that you still get a useful speed reduction. That minimum input size to handle a big torque will be pretty big on a two-stage setup, bigger than it would be if the pulley was hooked to the engine directly and capable of heading to the same maximum size. You have to pay the piper, and raising the shaft torque before it gets to the second CVT (and requiring a larger CVT) isn’t inherently better than just having a single larger CVT with both pulleys of sizes more like the second stage.

Besides, most engines don’t develop their max torque at low Rs anyway, so once the engine is going fast enough, step-down might actually hurt you. It’s counterintuitive, but a bigger CVT train which is still in its “slow” operating band can’t transmit as much power as a slightly smaller one in mid-band because the limiting factor is the smallest pulley in the equation. It’s *not* like a gear train where you can always just make the gears stronger or wider for a given ratio.

In any case, assume that the final stage (either alone or second in a pair) has to transmit a desired torque to the driveshaft. That torque is a force times a distance. For a given pulley diameter and desired torque, the surface force applied to that pulley literally has to be a certain magnitude, and the only way to get the force down is to make the pulley(s) bigger. The stage before that stage can get away with lower torque at output, but whatever pulley is the final recipient of output just has to be a certain size. If you have a more narrow range second stage, both pulleys can take up the same space while being “bigger” than otherwise, but not by a huge amount and it might not be by enough to cope with first stage torque multiplication. Given that the final stage is going to be nearly as big regardless whether you’re using one stage or two, the attractiveness of using two stages isn’t really there.

The only real plus that I’m seeing is if you’re trying to get to big torque with a weenie engine (the ability to extend the range to low engine speed with very high mechanical advantage *without* very high torque handling ability) and you don’t mind having the box very, very bulky to do it. That says one, and only one thing to me - delivery truck. Which, since many are diesels that are power choppy, vibratey (shock loads, hell on belts) and develop OK torque down low, not so much that either.

BloodlessWeevil

> BigBlock440

BloodlessWeevil

> BigBlock440

03/16/2016 at 18:34 |

|

You could use a torque converter to make up torque on the low end, or electric motors for the same purpose (see

e-CVT

.)